This article is based on the book How Innovation Works from Matt Ridley, and some reviews around it and why classical business approaches do not drive innovation.

The status quo is that on hardware development agile principles can’t be applied due to regulations: “bits are lightly regulated and atoms are heavily regulated.”.

But is it the over-regulation the root cause of slow pace of innovation in hardware? One thing is a fact, we still drive a car as 100 years ago with a steering wheel and some pedals, but from other side, we operate a telephone today in a very different way from 50 years ago.

Innovation is/should be a customer-centric activity: innovation begins from, and is driven by, the customer’s changing needs.

How Manufacturing Practices Prevent Innovation

Manufacturing processes have long cycle changes because they are designed to be slow.

In a large automaker company, if a team of engineers wants to redesign a car door, they may need to wait several years until the firm pay off the million dollar investment on the door mold machine.

Those companies might have engineers with innovative solutions for the car door, but the finance perspective has higher priority, and they are stuck.

Today, a multi-million manufacturing mold with a five or more year replacement cycle is usually not the only solution that is technically possible.

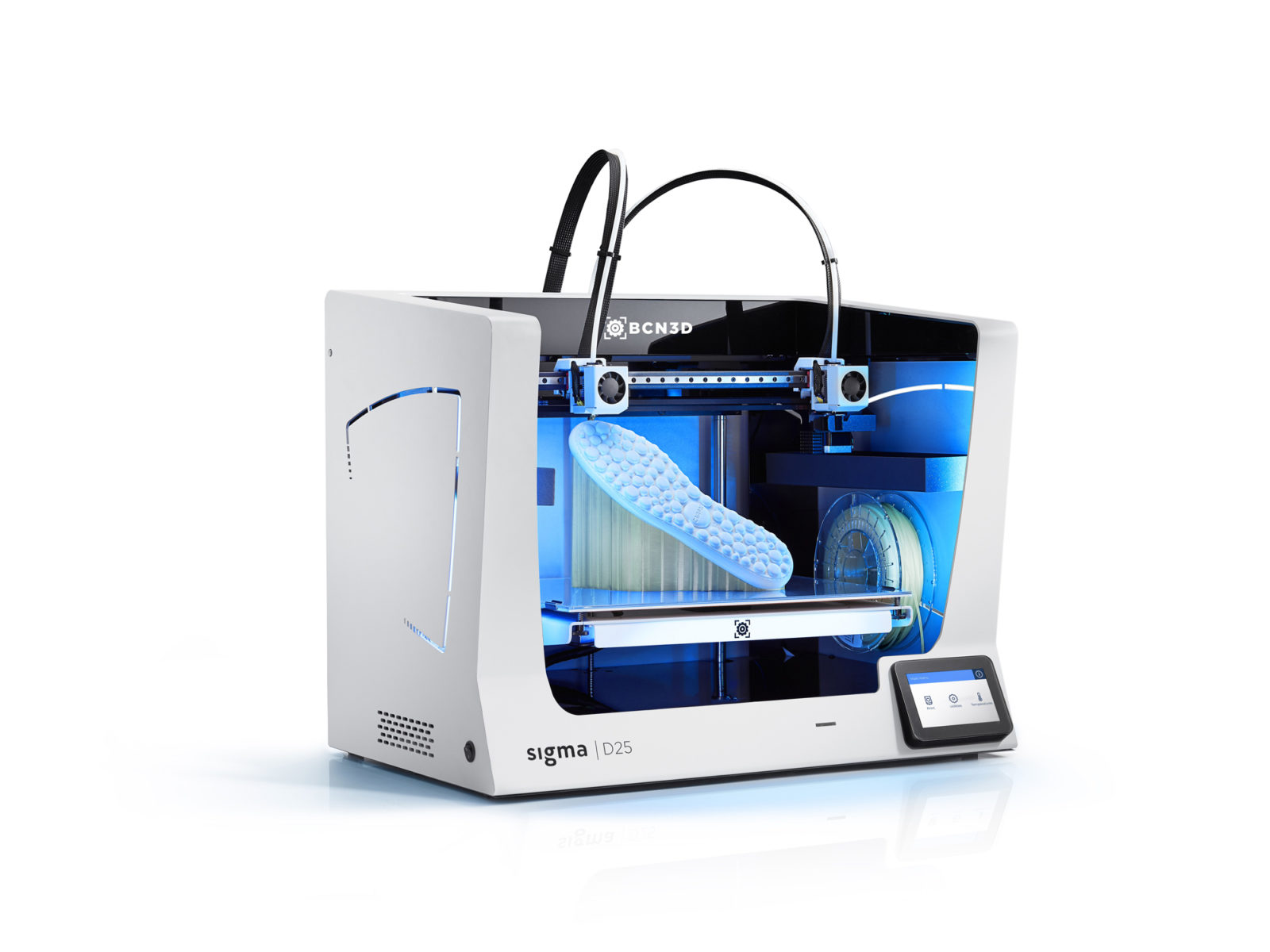

Modern 3D printing techniques are available to make rapid changes at relative low cost. Where is the problem then? Is on the management level, there is no will to do anything about the sunk cost in the multi-million door mold machine, and all the other hard to change equipment and processes.

In summary, You do the design and you install your multi-million mold machine and you are set for several years. That is, until you discover that your customer wants something different.

How Hardware Is Becoming More Agile

How car manufactures are catching up? At Tesla, for instance, there are investments in end-to-end 3D modeling systems (part of a digital twin system) from which they can view and simulate entire assemblies. Importantly, the software is fast, even when handling complex assemblies, so that engineers do not have to wait, which encourages a rapid iterative design approach.

Space-X also use agile approaches in hardware development. From Cliff Berg’s article “SpaceX’s Use of Agile Methods“. Instead of trying to perfect a design before it is tried and testing simulations, Space-X designs, simulates, builds, and tests often. “Instead of spending months or years on design and then carefully building one perfect prototype, they build many, and they test them all in myriad ways,” writes Berg. “They want to get the thing to the test stand, even if it has imperfections”.

3D printing in industrial systems is helping make the Hardware development more Agile.

“To reduce the cost of making parts whose design is always changing, they use 3D printing. This enables the design to evolve without requiring new dies to be fabricated: they literally just print a new design. It allows the design to rapidly evolve.”

“One does not wait for a design to be perfect before trying it: one tries it repeatedly and the outcome of each trial — each test — helps the design to converge much more rapidly than if one tried to perfect it beforehand through analysis. SpaceX’s approach to building something new is to break the problem down into a series of smaller problems, and solve them individually.”

Can Manufacturing Management Change?

Some are skeptical whether management can change. In is article “Why Hardware Must Embrace Agile Principles” thus a reference from a former CEO talk: “It is a sex change to get a hardware company to change its identity completely and act like a software one. What company has ever pulled that off?”

There are answers:

- Tesla and Space-X are the most obvious examples. You could argue that they were born Agile. But in any event, they demonstrate that it is possible to run a hardware company like a software company in an Agile fashion. Why doesn’t it happen? It seems that the management of the old manufacturing firms are reluctant to undertake, to use the same graphic terminology, “the necessary sex change operation.” In other words, it’s a leadership and management problem, not a problem of atoms versus bytes.

- Volvo Cars is heading in this direction, although they have only been at it since 2017. So, it is still early days.

- Haier is a notable example from China. Starting from a tiny bankrupt refrigerator factory in 1984, Haier is now the world’s largest appliance manufacturer. It has an estimated brand value of $16 billion and revenues in 2019 of $28 billion. How did that happen? They have explicitly followed the three principles of Agile—–customers, small teams, and networks—for a quarter of a century and the results speak for themselves. Interestingly, after they bought and took over GE Appliances, they discovered that GE Appliances was surprisingly bureaucratic and slow to innovate, despite the high-quality individuals who worked there.

“Customer focus” Thinking

Hardware firms appear to be mainly focused on making the hardware better, rather than thinking through: what could we do if we started from the new possibilities of software and then asked what hardware we might need? The hardware engineers still like to see themselves in charge with the old mindset of what the product is—a physical thing.

Thus, car companies are still mainly thinking of car as a metal transportation device with a few electronic gadgets attached to it.

They have yet to come to terms with the social reality that their product, like Tesla’s, has become a multifunctional entertainment center on wheels, with which we can even hold conversations and conduct business.

Many other sectors that deal with physical things are faced with similarly wrenching changes.

- A library goes from a physical collection of books with a software index to a website that may or may not have access to physical books.

- Movies shift from a physical cinema to online video streaming.

- An office shifts from being a physical building to an online network that may or may not have physical facilities associated with it.

The implications of these fundamental changes in thinking have yet to be fully grasped, even more in pandemic situations when digitalization transformation is mandatory.